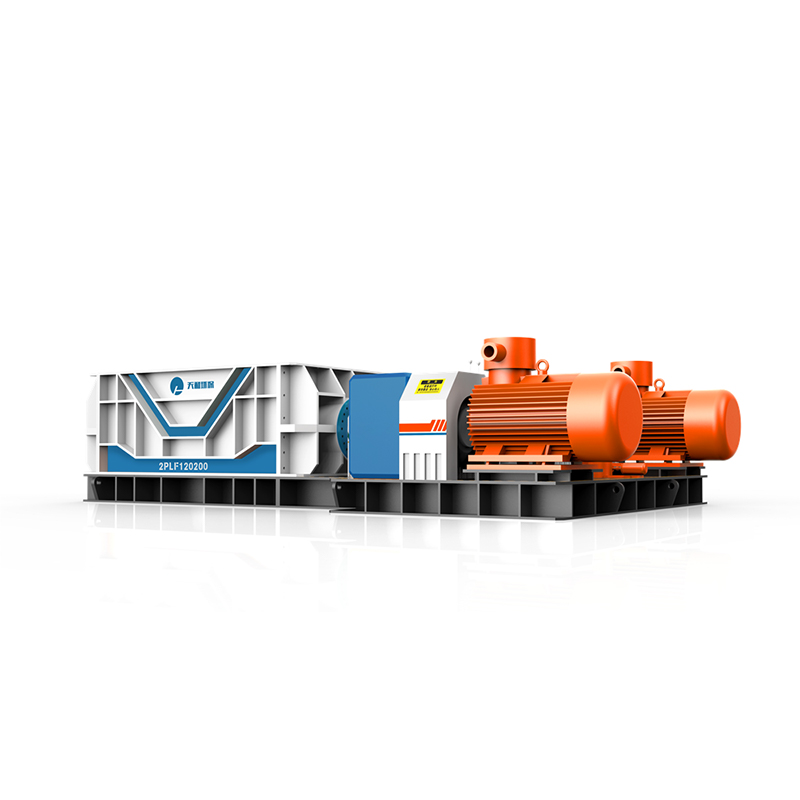

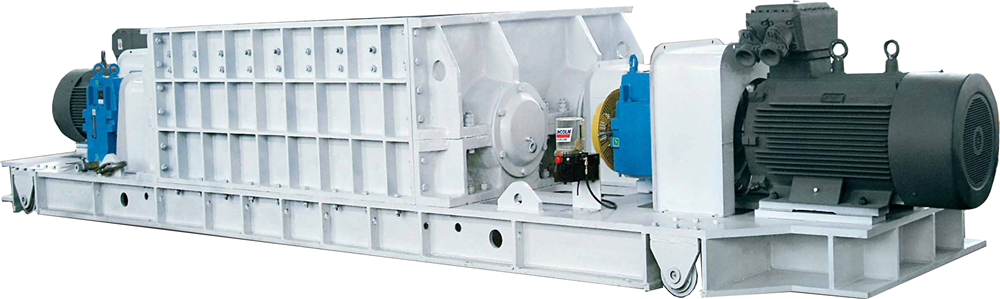

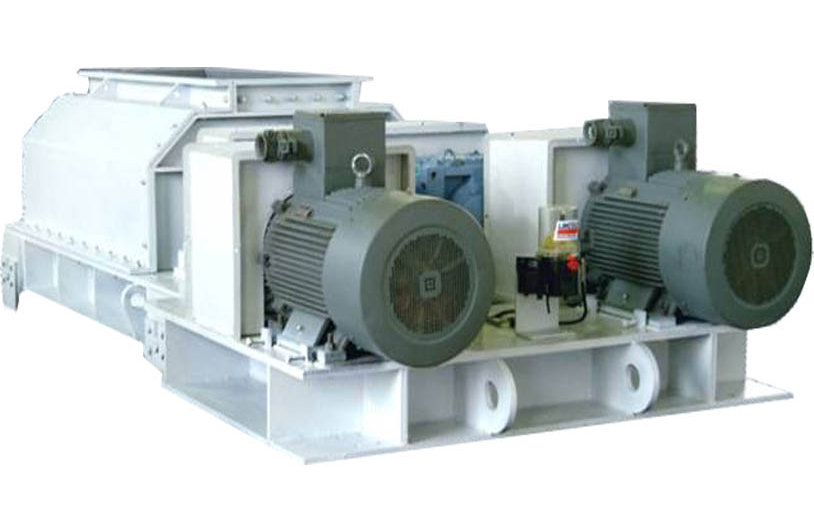

Double Roller Sizing Coal Sizer Screening Crusher

DOUBLE ROLLER SIZING CRUSHER

※ 2PLF series sizing crusher is a crushing equipment independently developed by our company for various coal crushing conditions

※ The crusher casing adopts the complete casing structure, which effectively solves the problem that the bearing of not firmly positioned,and keep the crushing chamber closed to ensure the working environment is cleaned

※ Crusher teeth material is babbitt wear-resistant alloy (HRC45-55, impact toughness 38Kg·m/cm2), with high hardness, high wear resistance, high toughness, strong impact resistance, etc., service life is the 2 - 3 times than common material

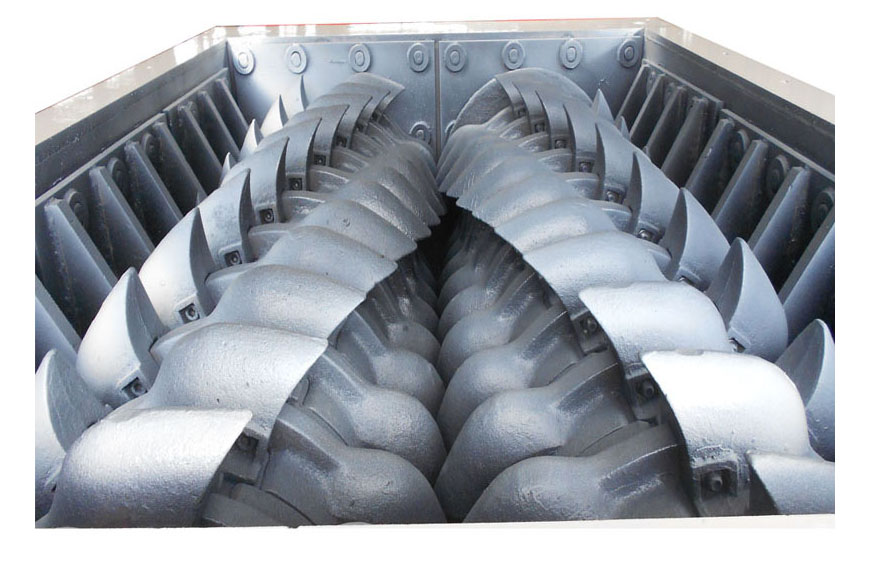

※ Various types of crusher teeth, movable teeth structure, ferrule structure, toothed ring structure, toothed plate structure and whole roller structure

※ Advanced arrangement of crusher teeth, single spiral, double spiral, multi-spiral, alternated type, straight type, etc., with high block rate and high crushing efficiency

※ The discharge size is adjustable, there are three adjustment method such as eccentric bearing device, screw and hydraulic method

※ Various of mobile device, such as fixed mobile device, screw-type mobile device, hydraulic and electric mobile device, facilitating daily maintenance and repairing

※ Equipped with advanced overload and stall protection device ,intelligent control system and auto-lubrication system, it is easy to operate and the equipment is safe and reliable

※ Coal industry materials crushing application for underground coal mine, coal washing plant, open-pit coal mine, etc. Such as lignite coal,brown coal, wood coal, bituminous coal, soft coal, anthracite coal, blind coal,semi-anthracite coal. Raw coal, middings (coal),cleaned coal, coking coal,baking coal,sintering coal, coal gangue, thermal coal, steam coal, oil shale, lignite coal, baking coal,filter cake of slime, hard coal, petroleum coke,crude oil coke,coal slime, lump coal, mixed coal, gross coal, run-of-mine coal, recarburizer,long flame coal, sintering ore,etc

※ Coal fired power plant industry such as boiler fuel and other coal fuel crushing

※ The mining and stone quarry such as gold ore,white sandstone, lead-zinc deposit,cooper ore, dolomite,Talcum, phosphate ore, rock phosphate, slag, basalt,etc

※ Aluminium manufacturer such as electrolyte anode

※ Chemical plant such as calcium carbide

※ Wet and sticky material crushing such as bauxite, laterite nickel ore,nickel ore, clay

※ Limestone quarry such as such as limestone 40-80mm, 50-90mm, 20-40mm, gypsum ,calcium carbonate,blue stone etc

※ Construction waste,building rubbish,etc

Primary sizing crusher, secondary sizing crusher, fine sizing crusher.

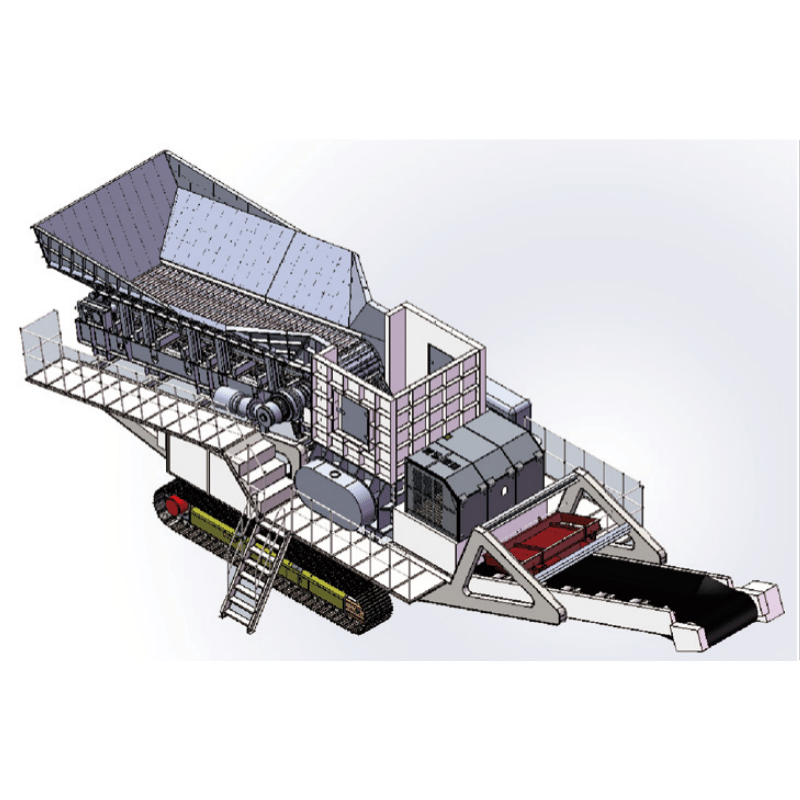

PRIMARY SIZING CRUSHER

※ Input size 300-1500 mm,output size 150-500 mm

※ Capacity up to 6000-8000 tons per hour

※ The crushing teeth are arranged in a spiral, and the lump rate is as high as 90% or more, and the over-crushing rate is low

※ The crushing teeth have various structures, such as movable teeth type, card sleeve type, tooth ring type and whole roller type

TECHNICAL DATA

|

Series |

Model |

Input Size (mm) |

Output Size (mm) |

Capacity (t/h) |

Motor Power (kw) |

|

CP75 |

2DSKP75100 |

400~500 |

150~200 |

200 |

2×55 |

|

2DSKP75150 |

400~500 |

150~200 |

400 |

2×75 |

|

|

2DSKP75200 |

400~500 |

150~200 |

600 |

2×110 |

|

|

CP80 |

2DSKP80100 |

500~600 |

200~300 |

200 |

2×55 |

|

2DSKP80150 |

500~600 |

200~300 |

500 |

2×90 |

|

|

2DSKP80200 |

500~600 |

200~300 |

800 |

2×132 |

|

|

2DSKP80250 |

500~600 |

200~300 |

1000 |

2×160 |

|

|

CP95 |

2DSKP95150 |

800~1000 |

200~300 |

1000 |

2×160 |

|

2DSKP95200 |

800~1000 |

200~300 |

2000 |

2×250 |

|

|

2DSKP95300 |

800~1000 |

200~300 |

4000 |

2×315 |

|

|

CP120 |

2DSKP120200 |

1200~1500 |

300~500 |

3000 |

2×250 |

|

2DSKP120300 |

1200~1500 |

300~500 |

5000 |

2×315 |

|

|

CP150 |

2DSKP150300 |

≤1500 |

250~350 |

8000 |

2*315 |

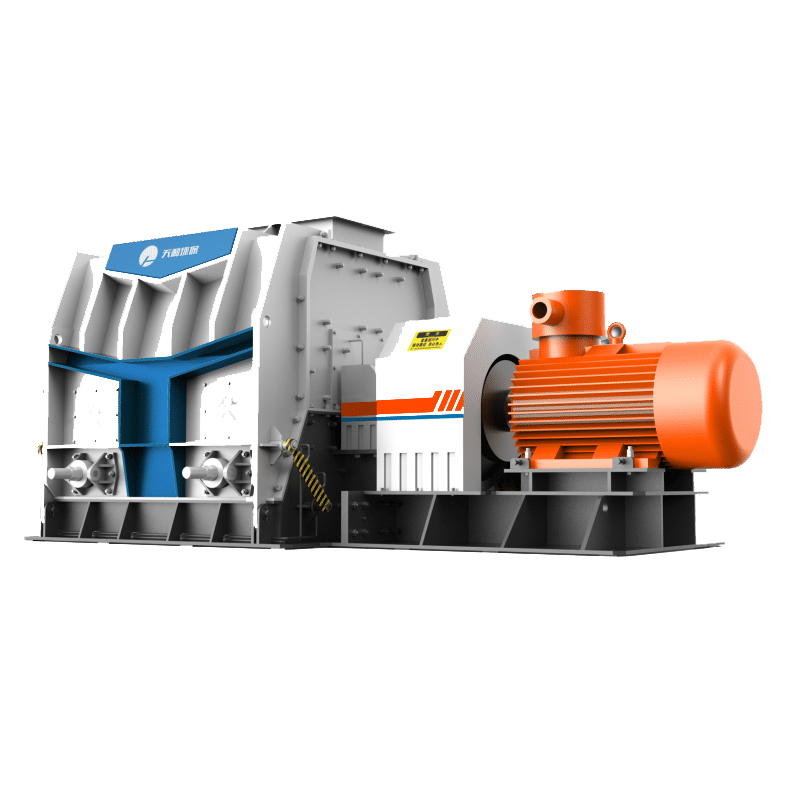

Secondary Sizing Crusher

※ Input size 150-500 mm, output size 40-150 mm, max capacity is up to 2000 t/h

※ The discharge size is adjustable, and various adjustment method are arranged, which is convenient to adjust and reliable in operation

※ Bullet type crushing tooth with spiral arrangement, strong ability to clamp material, super wear resistant

※ Toothed ring type, toothed plate type, whole roller type,etc

※ Special structure design of the main shaft, high torque transmission torque with high stability

Technical Data

|

Series |

Model |

Input Size (mm) |

Output size (mm) |

Capacity (t/h) |

Motor Power (kw) |

|

ZP70 |

2DSKP7070 |

250~300 |

50~80 |

70 |

2×22 |

|

2DSKP70100 |

250~300 |

50~80 |

130 |

2×30 |

|

|

2DSKP70150 |

250~300 |

50~80 |

200 |

2×45 |

|

|

2DSKP70200 |

250~300 |

50~80 |

400 |

2×75 |

|

|

ZP75 |

2DSKP75100 |

300~350 |

50~80 |

150 |

2×37 |

|

2DSKP75150 |

300~350 |

50~80 |

250 |

2×55 |

|

|

2DSKP75200 |

300~350 |

50~80 |

400 |

2×75 |

|

|

2DSKP75250 |

300~350 |

50~80 |

500 |

2×110 |

|

|

ZP80 |

2DSKP80100 |

350~400 |

80~100 |

150 |

2×45 |

|

2DSKP80150 |

350~400 |

80~100 |

300 |

2×75 |

|

|

2DSKP80200 |

350~400 |

80~100 |

600 |

2×110 |

|

|

2DSKP80250 |

350~400 |

80~100 |

800 |

2×160 |

|

|

2DSKP80300 |

350~400 |

80~100 |

1000 |

2×200 |

|

|

ZP90 |

2DSKP90100 |

400~450 |

100~150 |

200 |

2×55 |

|

2DSKP90150 |

400~450 |

100~150 |

300 |

2×75 |

|

|

2DSKP90200 |

400~450 |

100~150 |

600 |

2×132 |

|

|

2DSKP90250 |

400~450 |

100~150 |

800 |

2×160 |

|

|

2DSKP90300 |

400~450 |

100~150 |

1200 |

2×250 |

|

|

ZP100 |

2DSKP100200 |

450~500 |

100~150 |

600 |

2×160 |

|

2DSKP100250 |

450~500 |

100~150 |

800 |

2×200 |

|

|

2DSKP100300 |

450~500 |

100~150 |

1200 |

2×250 |

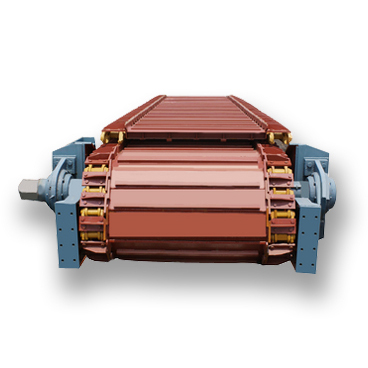

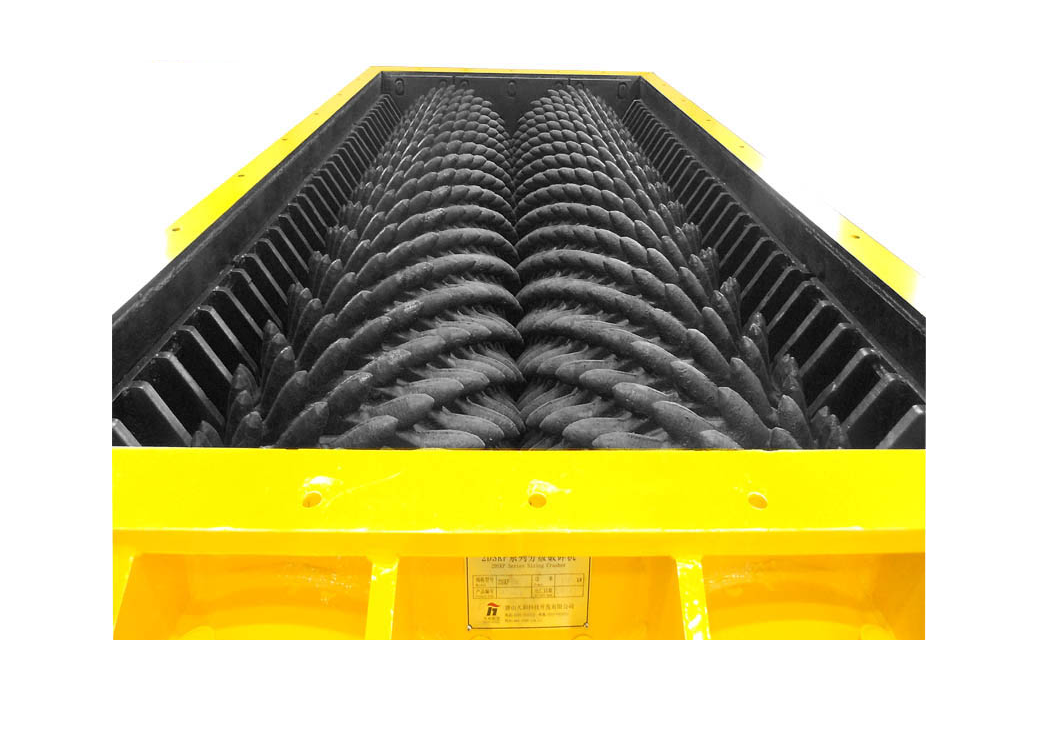

Fine Sizing Crusher

※ Input size 50-150 mm, output size 15-40 mm, max capacity is up to 500 t/h

※ Special tooth design, high lump rate, low over-grinding rate

※ Optimized design of tooth height, width and thickness, with strong biting ability and long service life

※ Equipped with side cleaning device, the wet and sticky material can be crushed normally

Technical Data

|

Series |

Model |

Input Size(mm) |

output size(mm) |

Capacity (t/h) |

Motor Power (kw) |

|

XP65 |

2DSKP65100 |

50~80 |

30 |

100 |

2×37 |

|

2DSKP65150 |

50~80 |

30 |

150 |

2×45 |

|

|

2DSKP65200 |

50~80 |

30 |

200 |

2×55 |

|

|

XP75 |

2DSKP75100 |

80~100 |

30 |

100 |

2×45 |

|

2DSKP75150 |

80~100 |

30 |

150 |

2×55 |

|

|

2DSKP75200 |

80~100 |

30 |

200 |

2×75 |